Services

Goal-oriented, professional, responsible

NTEC offers engineering services in the field of e-vehicle and combustion engine development

NTEC realizes the assembly for EV assembly customization electrically & mechanically

NTEC supports tendering for electric mobility projects (urban mobility buses and special vehicles for industrial applications)

NTEC uses many years of experience from cooperation with manufacturers

NTEC accompanies procurement and sourcing

NTEC determines project costs (concept, feasibility, prototype, project planning)

NTEC develops complete vehicle concepts, from design to prototype

NTEC realizes the construction of the prototype in-house

NTEC offers fleet testing or individual processing of test work

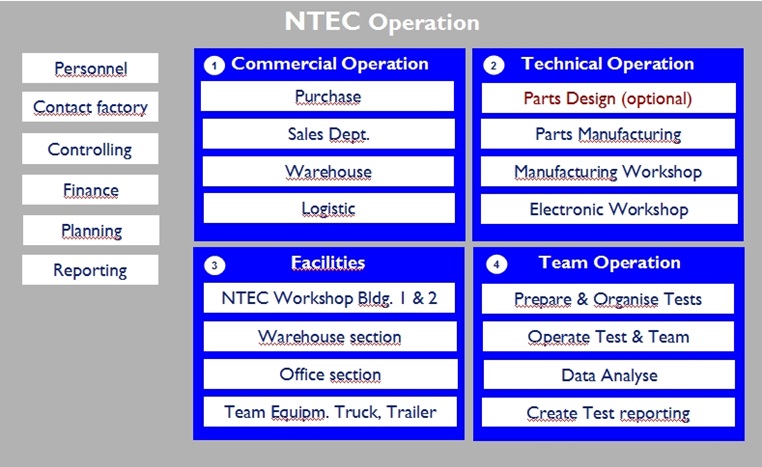

NTEC Operations – the all-round carefree package

We have experience in the construction, integration and testing of vehicles with combustion engines or electric drives since 1999

As an independent company, we always see the overall project

We can also test and trial under difficult conditions

NTEC Commercial Operation “1”

The NTEC Back Office handles purchasing, parts management, storage and retrieval of OE components, purchased parts or assemblies for our customers. In addition to logistics, it is also possible to manage runtime and service life data on the part or via our warehouse system.

NTEC Technical Operation “2”

In addition to design and CAE, prototype parts can be produced using manual or CNC technology, including digital printing processes. Data exchange with customers can be realized by Step or native Unigraphics data. In the electronics workshop, all components for vehicle electrics can be controlled with analog and digital sensors, actuators with specially developed PDU or CAN bus systems.

NTEC Facilities “3”

NTEC Workshop Buildings 1 & 2 allow the construction of vehicles, their components etc. on 1000 m2.

The testing technology is available in-house.

Small series production in batches of 100 is possible.

NTEC Team Operation “4”

The team operation is the test team, its organization and the associated data acquisition technology as well as its evaluation.

NTEC – everything possible at one location

We offer 1400 m² of hall space

A mechanical production facility for the manufacture of component samples

Welding technology for stainless steel and aluminum alloys

Over 1000 m² of storage space

EDP merchandise management

Bead blasting and coating technology (powder coating)